|

|

|||||

|

||||||

TT-Tracks© Modules that have been Built

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 1 | Tower Module | 2011 | In Service | To be measured |

| Notes | This first module is built on a Woodland Scenics foam base with scenery material from many manufacturers. Often used as a test bed for new scenery items. It now has leveller feet. | |||

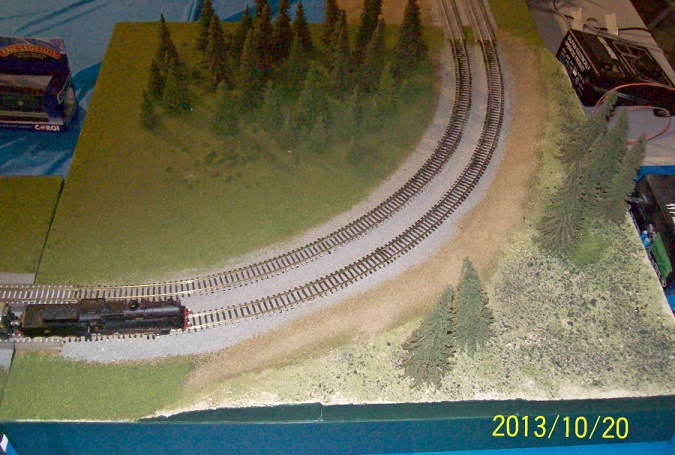

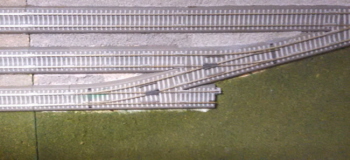

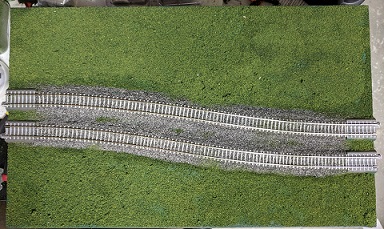

| Pictures | A long time ago this FIRST module started as :

|

|||

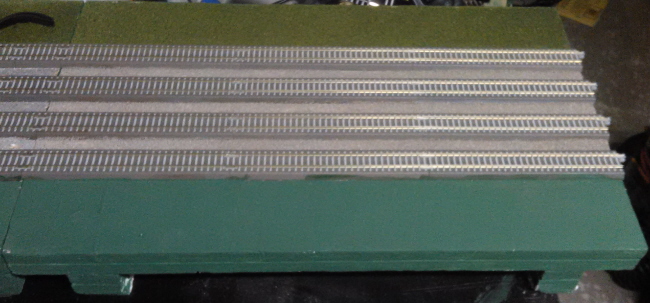

and now in 2013 it has progressed to this:

|

||||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 2 | Power Corner | 2011 | Out of service after Trains 2011. To Bjoern. To Tibi. | To be measured |

| Notes | This Standard corner has R1 and R2 curves. These proved to be too sharp for North American equipment, thus they were taken out of service after Trains 2011. It was sold to Bjoern for use in his reverse loop project. Now owned by Tibi. | |||

| Pictures |

This is as far as this corner had progressed. Home made raffia trees on the outside and Woodland Scenics Canopy Trees on the inside. The power connections are buried under the raffia trees. It has a blue foam base, styrene fascia and scenery by various Woodland Scenics products. |

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 3 | Front Right Corner | 2011 | Out of service after Trains 2011. To Bjoern. To Tibi. | To be measured |

| Notes | This Standard corner has R1 and R2 curves. Taken out of service sfter Trains 2011. It was sold to Bjoern for use in his reverse loop project. Now owned by Tibi. | |||

| Pictures |

The matching corner to the power corner. Here are the two right hand corners with the Woodland Scenics Canopy Trees on the inside. It has a blue foam base, styrene fascia and scenery by various Woodland Scenics products. |

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 4 | Front Left Corner | 2011 | Out of service after Trains 2011. To Bjoern. To Tibi. | To be measured |

| Notes | Built on a blue foam base, this Standard corner has R1 and R2 curves. Taken out of service after Trains 2011. It was sold to Bjoern for use in his reverse loop project. Now owned by Tibi. | |||

| Pictures |

This image shows both of the left end corners in their final configuration. The third line of track was Tillig R3 section track in their ballast base. It was loose on the surface. |

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 5 | Rear Left Corner | 2011 | Out of service after Trains 2011. To Bjoern. To Tibi. | To be measured |

| Notes | The matching corner to the Front Left Corner. Built on a blue foam base, this Standard corner has R1 and R2 curves. The Woodland Scenics Hedgerow was added as a scenic break. Taken out of service after Trains 2011. It was sold to Bjoern for use in his reverse loop project. Now owned by Tibi. | |||

| Pictures |

This image shows both of the left end corners in their final configuration. The third line of track was Tillig R3 section track in their ballast base. It was loose on the surface. The train shown is from my first Tillig train Set. |

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 6 | Farm Module | 2011 | In Service | To be measured |

| Notes | This two track to three track module with a right hand crossover is built on a

plywood base. It started out plain, then the fields, fence and hedges were added, and finally the

small Auhagen barn. Years of use have taken their toll on the fence. It needs rebuilding or replacing.

Changes are coming to this module. The crossover will be removed and the front turnout replaced with a #6. This will require replacing the fence and redoing the front scenery. In 2018 a Farm Yard sound module was added. Currently controlled by a pushbutton. As the station corner will be out of service soon, this module will bhe left as it is. |

|||

| Pictures |  |

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

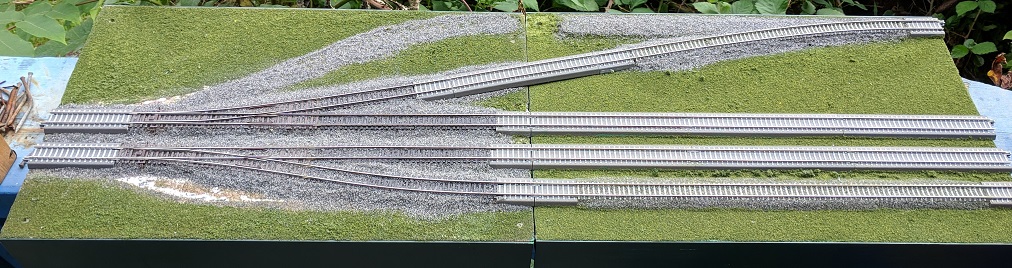

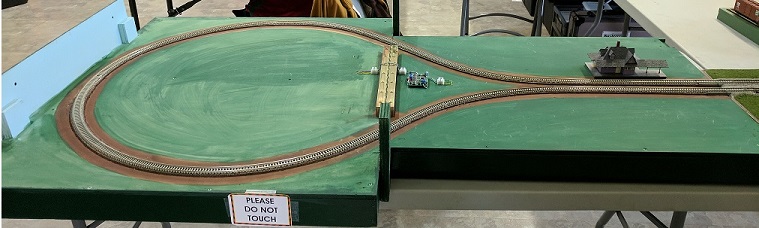

| 7 | Wye Access Module | 2011 | In Service | To be measured |

| Notes | This two track to three track module with a left hand crossover started out as a mirror image of module 6. In 2013 the front line was extended to be part of the wye. Then the rear line was added as an industrial access line to the Station corner. It is built on a plywood base. In 2017 track jumpers were added to route power past turnouts that were no longer passing power through. | |||

| Pictures |

|

|||

| Notes | Marh 2020. The crossovers were removed from this module. | |||

| Pictures | ||||

| Module Number |

Module Description | Year in Service |

Status | Offset |

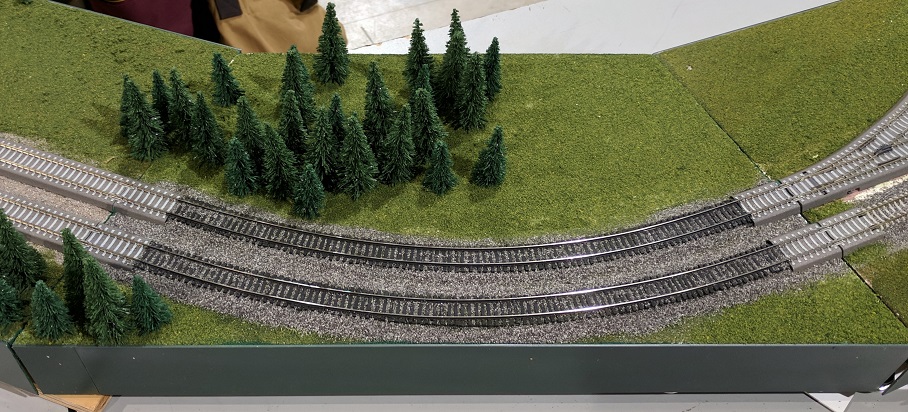

| 8 | Plain Straight Module | 2011 | In Service | To be measured |

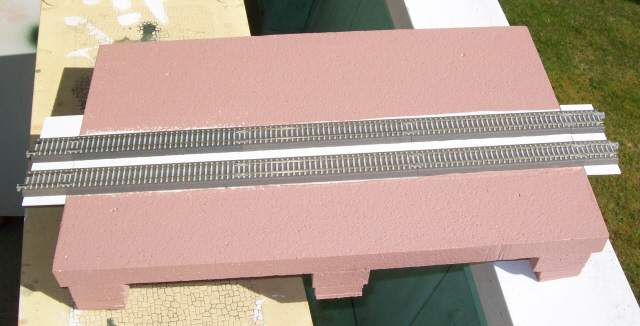

| Notes | This plain straight module was built to balance the Tower Module. At various times it has provided space for Temporary structures. Built on a Woodland Scenics Foam base. | |||

| Pictures |  |

|||

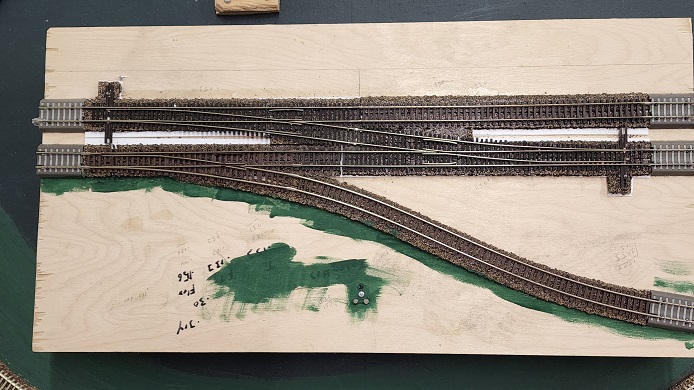

| Notes | At one point it was stripped of its track and sat unused. In 2017 it was rebuilt as a new junction to access the back industrial track. First showing at Chilliwack 2017. It needs scenery work. The two straight mainline sections are rail in tie strips on N-Scale cork and a .020" styrene shim. | |||

| Pictures |  |

|||

| 2018 | A turnout has been added to the front line to connect with the third line on the city corner. The scenery has been upgraded.

This module will be the first to have its turnouts replaced by #6s. First the front line, then the back line. The back line will require a revised track alignment across this module and module # 29. |

|||

| Pictures |  |

|||

| 2018-09 | Module 08 has been rebuilt with Kuehn #6 turnouts. One was broken and rebuilt.

This was the third rebuilding of some of the track and has shown the limits of the rebuilding

process. Removing the glued down track from a foam module damages the surface.

The foam surface is very rough after track has been removed twice.

Module 29 has had its back track reliagned to meet the rebult module 08. The scenery has been touched up to cover the bald spots. Turnout control is currently manual. |

|||

| Pictures |  Modules 08 and 29 rebuilt. Modules 08 and 29 rebuilt. |

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

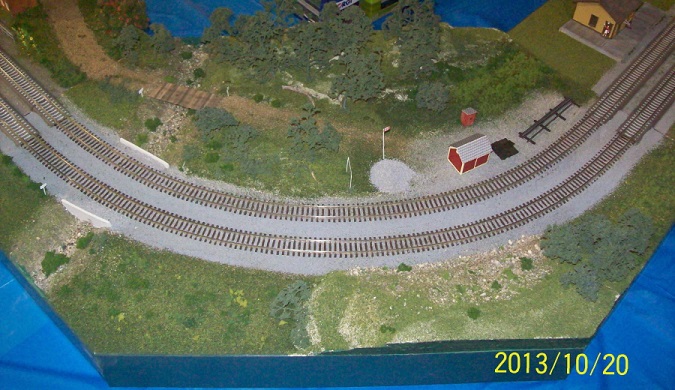

| 9 | Diamond Corner | 2011 | In Service | To be measured |

| Notes | This was the first Large corner made. Nominal R4/R5 curves. Made from WS 1" foam sheets layered to make a two

foot square then the front and rear corners were cut off. Used in our first setup in 2011 and in every display since then.

This corner has a single power connector. |

|||

| Pictures |

|

|||

| Notes | This corner languished as a rather barren green

module until it was brought up to this level of completion in 2013. Forms a module pair with the first module.

As of 2017 it is suffering a bit from wear and tear but is still in use. It will probably be the last large corner in regular service. It should be noted that the designation "Large" corner was made when we were using the original R1/R2 corners. We have since then gone to much larger corners that are now designated by the degree of curvature on each module: 45 degree, 30 degree and possibly to come: 22.5 degree. |

|||

| Pictures |

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 10 | Inside Corner | 2011 | Repurposed - See module 16 | Non Standard. |

| Notes | R1/R2 curves. Made from blue foam. It was used in the the L-Shaped layout

shown at Trains 2011. It was set aside and ignored for a few years.

See module 16 for its current configuration. |

|||

| Pictures |

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

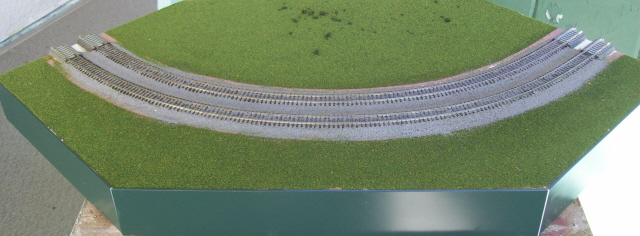

| 11 | Large Corner | 2012 | Stored Serviceable | To be Measured |

| Notes | Nominal R4/R5 curves made from flex track. Built on a two foot square

plywood canvas which I found out much later was neither square nor two feet! Still in a state of

flux as to how this will be finished. My current thoughts are to move most of the existing trees to

outside the curve and build a logging camp using the Bunk House kits from Model Logging

Supply. As with the standard corner the power connectors are under the trees to the right.

This was replaced by module 13 as the power connection to the layout. As we have moved away from donut displays to a Loop to Loop setup, this module is stored serviciable. |

|||

| Pictures |

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 12 | Station Corner - Large Corner | 2012 | In Service | To be Measured |

| Notes | Nominal R4/R5/R6 curves made from flex track. Built on a nominally two foot

square plywood painters canvas (neither square of two feet). The back line is an industrial spur line to service industries along

the back side of several modules. It reconnects to the mail line several modules over on my

bridge module. The Brick structure, BTS Loading dock and the track serving them were added in

2015. The Auhagen Klasdorf station is close enough to a US style station to use. Much detail

work needs to be done on the station scene and the road.

2018 - Still in use in most Loop to Loop setups. The station is suffering from wear and handling. Stored serviceable in 2019. Power connectors removed for reuse on new modules. |

|||

| Pictures |

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 13 | Wye Corner - Large Corner | 2012 | Stored Serviceable | To be Measured |

| Notes | Nominal R4/R5 curves made from flex track. Built on a nominally two foot

square plywood painters canvas. This started as two tracks on a bare green module.

In 2013 the front track was added to access the staging yard. Then the right track was added along with module 16 (rebult module 10) to form two sides of the wye. The back track leads off to the station corner. The elevated track was supposed to provide a scenic break but it looks like it will interfere with the road. Much remains to be done on this module. This replaced module 11 as the power connection to the layout. Made redundant 2017 with new broad corners. The straight track along the front has been removed for use elsewhere. Stored serviciable. Power cable connections removed late 2018 for reuse on the 30 degree corner set. |

|||

| Pictures |

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 14 | Fudge Module - Non Standard Straight Module | 2012 | In Service | To be Measured |

| Notes | As noted above the two foot square plywood painters canvases are neither two feet or square. This module makes up for some of the alignment issues caused by those corners. No idea about final scenery. On larger displays this is not a big issue. | |||

| Notes | January 2020. Module to Xenia for scenicing. | |||

| Pictures |

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 15 | Wye - Staging Junction Module | 2013 | Stored Serviceable | To be Measured |

| Notes | This started as a straight two track module. Then the front line leading to the

wye was added. Then the rear line leading through two modules to the City Corner. The straight

piece of track crossing the module joint is removeable.

For the 2015 show the back line was modified to fit a turnout leading to the left. What is going to happen with the scenery has not been decided. Built on a foam base. 2018 - as the corner wye is not currently used, this module is out of service. If the corner wye is offically abandoned, this module will be stripped of track and repurposed otherwise it will be stored seviciable. 2019 rebuilt. See below. |

|||

| Pictures |

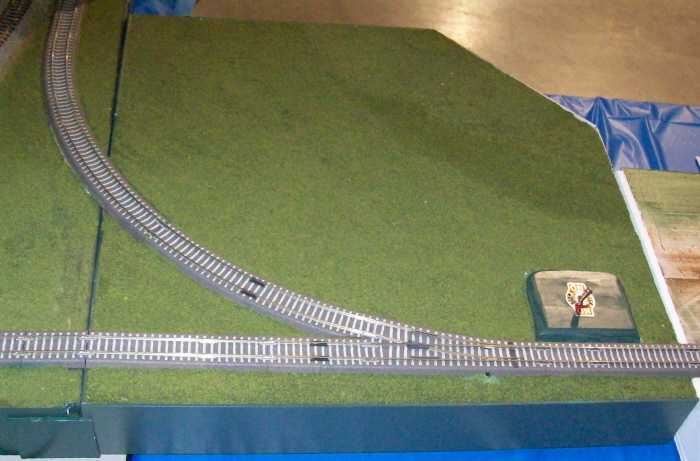

Shown here in its Portland configuration, the small two track yard is loose bedding track.

|

|||

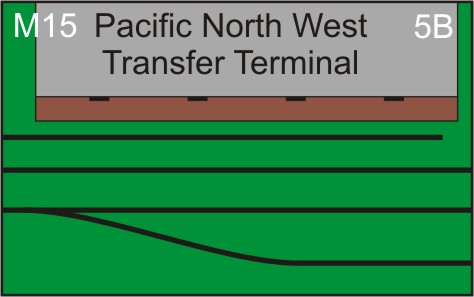

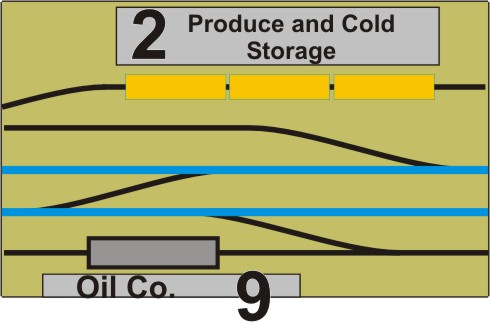

| Notes | 2019 rebult as the first module of the five module industrial area. 2020 another track added. | |||

| Pictures |

Plan of rebuilt module 15.

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 16 | Right Hand Wye Module | 2013 | Stripped of materials | N/A |

| Notes | The former inside corner(module 10) was rebuilt to this. It uses R2 which is a bit

sharp for some equipment but as it is only ever crossed at slow speeds it is OK. The curved piece

of track that crosses the module joint is removeable.

Power control is by the switch on the module. If you want to enter/exit from the front track, throw the switch that way. Similarly if you want to enter/exit from the rear track, throw the switch that way. If the switch is in the center the power is off. This low tech power control method was chosen because it works with both DC and DCC. A DCC auto reverse module would have precluded DC operation. As the staging yard is connected to the right, this switch also controls the power to the staging track. Built on a foam base. In 2016 the reversing switch was replaced by a Dual Frog Juicer to hande auto reversing. 2019 - stored serviceable. Stripped of some track, insulated rail joiners, and the Dual Frog Juicer to use on first new Teardrop Reverse Loop - Module 49. When the rest of the track is removed, the carcass will be stored for possible reuse. |

|||

| Pictures |

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 17 | Right Hand Staging Yard Ladder | 2012 | Salvaged. Out of service. | N/A |

| Notes | Built by Terry Chatelaine in 2012 the staging yard passed into my hands in 2013. A front fascia was added. Grass and ballast between the track were added. As it appears that this module will be used in displays with the public on both sides, fascia will be added on the back side. | |||

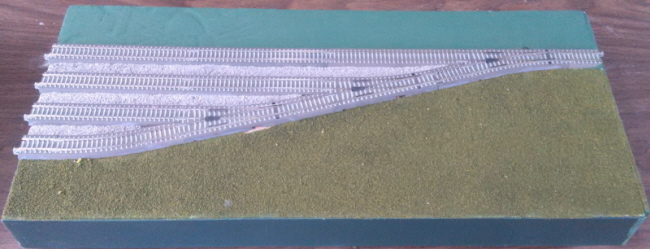

| Pictures |

|

|||

|

||||

| Sept 13, 2015. The left end ladder has been modified by adding a Left hand Turnout to the top line. | ||||

| Notes | 2017 - To Tibi for rebuilding. | |||

| Notes | 2018 - replaced by new six track staging yard. Track salvaged for new yard. | |||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 18 | Staging Yard Mid Section | 2012 | Salvaged. Out of Service | To be Measured |

| Notes | Built by Terry Chatelaine in 2012 the staging yard passed into my hands in 2013. A front fascia was added. Grass, and ballast between the tracks were added. As it appears that this module will be used in displays with the public on both sides, fascia will be added on the back side. | |||

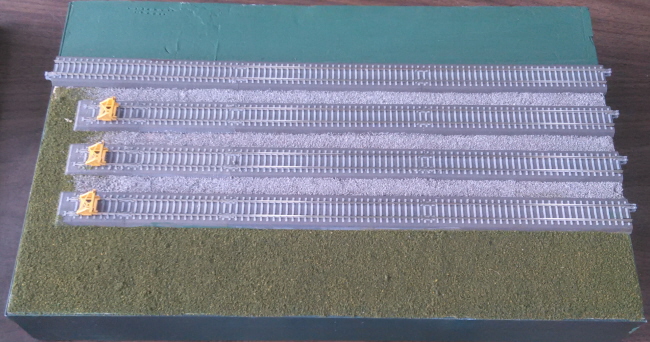

| Pictures | The middle staging module.

|

|||

| Notes | 2017 - To Tibi for rebuilding. | |||

| Notes | 2018 - replaced by new six track staging yard. Track salvaged for new yard. | |||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 19 | Staging Yard End Section | 2012 | Salvaged. Out of Service | To be Measured |

| Notes | Built by Terry Chatelaine in 2012 the staging yard passed into my hands in

2013. A front fascia was added. Grass, and ballast between the tracks were added. As it appears

that this module will be used in displays with the public on both sides, fascia will be added on

the back side.

With talk of a right end ladder being made, this module needs a few changes. The bumpers on three tracks need to be removed and the track extended to the edge of the module. For displays where the second staging ladder will not be used, a small (2" wide) non standard module will be made with four track bumpers on it. This can be plugged on the end to terminate the tracks properly. |

|||

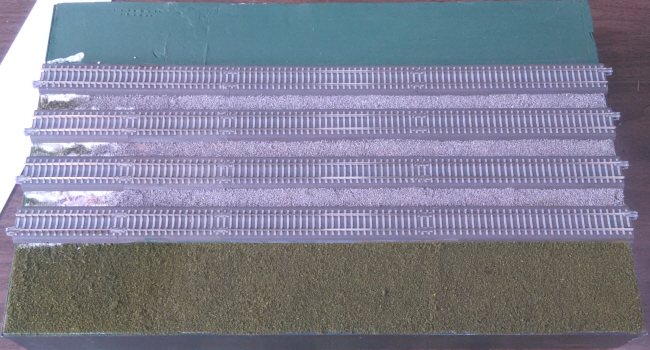

| Pictures | End Staging Module..

|

|||

The modified end staging module.

|

||||

| Notes | Happily with the track glued to the foam it was an easy matter to slip a putty knife under the track and pop it off. The bumpers were replaced with BG2 straight track sections. After the glue dries the ballast and grass will be touched up. | |||

| Notes | As of the end of 2017, all staging yard modules are in Tibis hands for rebuilding. | |||

| Notes | 2018 - replaced by new six track staging yard. Track salvaged for new yard. | |||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 19a | Staging Yard End Cap | 2015 | No Longer Needed | To be Measured |

| Notes | The bumpers formerly on the right end of the right-hand staging module have been removed and mounted on this small end cap. It will be used to terminate the staging yard when the right hand staging yard ladder is not used. | |||

| Pictures | Staging Module End Cap as originally built.

|

|||

| Notes | 2018 - With the new six track staging yard, this piece is no longer needed. Track will be salvaged. | |||

| Notes | 2019 - Module will be rebuilt to be the industrial area end cap with bumpers set at the front track (to match the lumber yard spur), the two main lines, and the back track to match the cattle pen spur. The scenery has since been touched up. | |||

| Pictures | Staging Module End Cap as rebuilt for Industrial area.

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 20 | Fast Tracks Crossover Module | 2014 | In Service | To be Measured |

| Notes | This module was built to host a code 55 #6 crossover built using a Fast Tracks

HOm turnout jig. At the time I did not expect Fast Tracks to make any TT-Scale modules so I

purchased an HOm jig as it is the same gauge (12mm) as TT-scale. With a bit of fiddling with

the tie spacing a reasonable result was obtained. With the exception of the end Bedding Track

connection pieces, the straight track was hand laid on PC and wood ties. The turnouts work well

with North American equipment but not with European equipment with deep flanges.

Now of course Fast Tracks makes TT-Scale jigs in code 55 and code 70, for #6 and #8 turnouts. Shown sitting on the module are the two TT-Scale turnouts I built at the Modeling With The Masters Fast Tracks clinic at the Portland 2015 NMRA National convention. I have discussed with Fast Tracks on how to modify these so they will handle European equipment. 2018-07 - The turnouts have been modified to have wider flangways. Testing with a single cars show they work OK. This weekends setup at the BCSME (Sept 2018) has shown they work with everything but Triang equipment. That equipment will have to be modified to work with these turnouts. As of August 2018 the turnout controls have been moved to the rear of the module to keep them out of reach of little hands. As I now have proper TT-Scale Fast Tracks jigs, the HOm jig has been sold to a HOm modeller. |

|||

| Pictures |

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 21 | Back Track Access Non Standard Straight Module | 2015 | In Service | To be Measured |

| Notes | This short module (about 11" wide) module was built to provide access to the back industrial spur on the Station corner. The three lines of straight track at the front are flex track with the rails extended to the end of the Bedding Track connection pieces. The oil spur in the back is conjecture right now but will most likely happen. | |||

| Pictures |

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

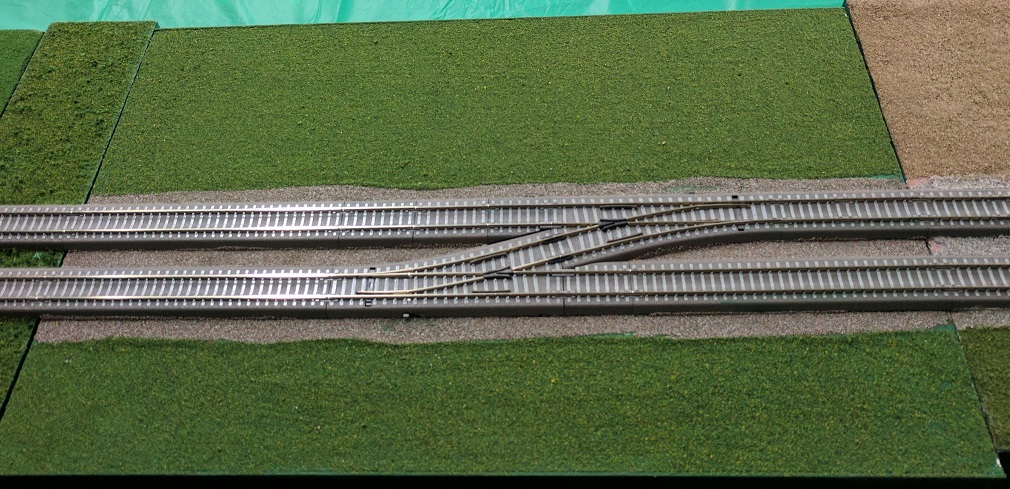

| 22 | Mini RH Crossover Non Standard Straight Module | 2015 | Out of Service | To be Measured |

| Notes | This short module (about 11" wide) module was built to balance the non-standard

Back Track Access module on the front of the display. There was just enough space for the RH

crossover that was needed to provide better access to the wye track. Another layer of scenery

material has been added since this picture was taken.

This module failed at VTE 2017. The connections in the turnouts stopped conducting power. This was fixed in 2018 after the Western Rails 2017 display. Jumpers were added to both turnouts to conduct power past the bad turnout connections. |

|||

| Pictures |

|

|||

| Notes | March 2020 this module was striped of its track and is currently out of service.

This will be rebuilt as the new short bridge module. |

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

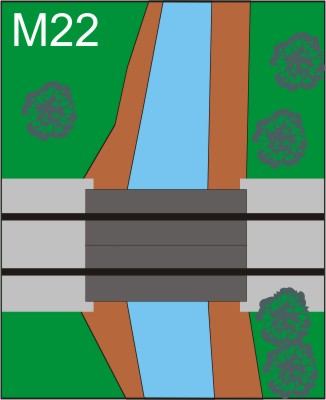

| 22r | Short Bridge Module | Material gathering | 86mm | |

| Notes | This will be a half length module with a bridge over a stream

using modified Atlas N-Scale through Girder bridges with CNR Slogans on them.

Rebuilt om part of Module 22 carcass.

Due to the constraints imposed by our method of module transport, we can't go up very much, but we can go down. Stream can be 1"(one layer of foam) deep. |

|||

| Pictures | . Plan of Rebuilt module 22. Plan of Rebuilt module 22.

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

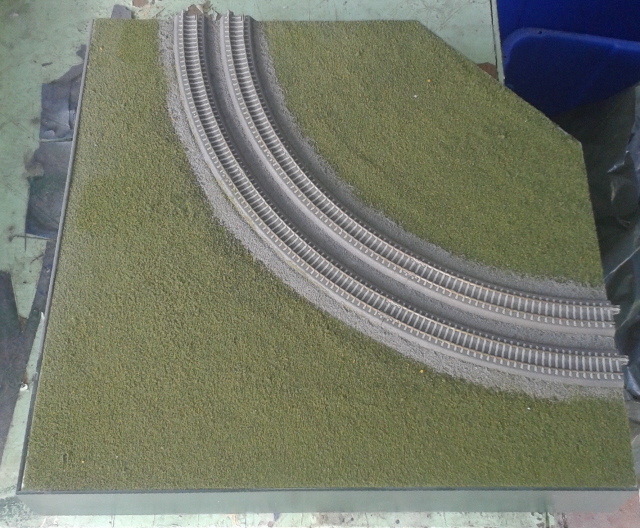

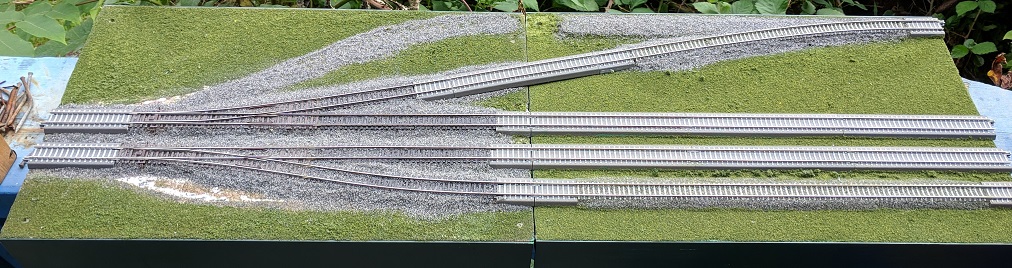

| 23 | LH Crossover Straight Module | 2015 | In Service | To be Measured |

| Notes | This LH Cross Over Module was built to balance the RH crossover on the Mini Crossover Module. It usually sits on the right end of the display. Terrain to be determined. | |||

| Pictures |

|

|||

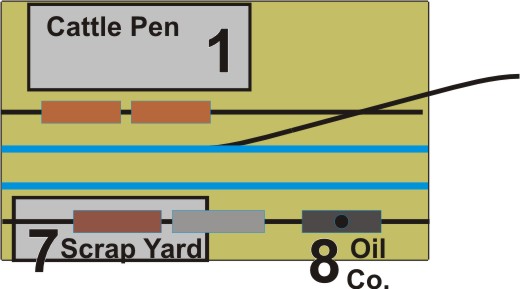

| Notes | March 2020 - rebuilt as the second module in the industrial area. | |||

| Pictures |

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 24 | Half Depth Straight Module #1 | 2015 | In Service | Non Standard |

| Notes | In the planning process for the 2015 Portland NMRA Train Show it was determined that a pair of filler modules would be needed to set up the display on Wednesday. These turned out to be necessary for the display on all days. They are Standard width but only half depth with the two track lines centered on the module ends. Flex track was used between the Bedding Track end pieces with the flex track rail continued through the Bedding Track base pieces to the module ends. Built out of foam. | |||

| Pictures | This image shows both modules.

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 25 | Half Depth Straight Module #2 | 2015 | In Service | Non Standard |

| Notes | The second half depth module. Built the same way as the first module. | |||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 26 | Bridge Junction Module | 2015 | In Service | To be measured. |

| Notes | This module was started in 2013. Progress stalled for a long time. Finally the basic module was finished before Portland. The bridge trestles were constructed in my motel room in Portland and installed on the module the Thursday before the show. The back track continues behind the farm Module to join the switching lead from the Station Module. Built out of foam. Scratch built mainline bridge (styrene and balsa) with a widened Atlas N-Scale bridge on the rear line. | |||

| Notes | With the start of the #6 Turnout project it is not certain what to do with this module. The turnout could be replaced with a #6 but it would not be possible to connect to the back track without another module. This is the access to the rear industrial module set. | |||

| Pictures | .

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 27 | Straight Module | 2015 | To Bjoern | To be measured. |

| Notes | This filler module was made just in case it was needed for the Portland NMRA show. The basic ground cover was not finished. It spent the show behind the Farm Module holding the back track from the Bridge Junction Module. As it was built with track provided by Bjoern the module was given to him for use at home. He rebuilt it to use with his staging yard return loop module set. Now with Tibi. | |||

| Pictures | .

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 28a and 28b | Straight Split Module | 2015 | In service | Non Standard |

| Notes | This standard straight module is cut diagonally to make a triangular shaped filer piece behind the Bridge Junction Module and the Farm Module. It has track from the Bridge Junction Module to the Back Track Access module on it. It is built out of foam. | |||

| Pictures | .

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 29 | Straight Module | 2016 | In service | To Be Measured |

| Notes | This standard straight four track module is used with module 7 to expand the width of the display. It is built out of foam. | |||

| Pictures | .

|

|||

| 2018-09 | Module 29 has had its back track reliagned to meet the rebult module 08. The bare scenery areas have been touched up. | |||

| Pictures |  Modules 08 and 29 rebuilt before scenery touchup. Modules 08 and 29 rebuilt before scenery touchup. |

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 30 | Straight Module | 2016 | In service 2016 | To Be Measured |

| Notes | Indianapolis needed another module or two to complete the basic display. This standard straight module is built out of foam. | |||

| Pictures | .

|

|||

| 20108 | The module featured (poorly) an abandoned rail spur. This has been turned into a full working spur. | |||

| Pictures | .

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 31 => 31a & 31b | Straight Module | 2016 | In Service | To Be Measured |

| Notes | Indianapolis needed another module to complete the basic display. This standard straight module is built out of foam. It features an abandoned rail line crossing the two mainlines. | |||

| Pictures | .

|

|||

| Notes | In 2017 as new larger corners were being brought into service it was determined

that we needed partial modules to make the display fit on the tables we are supplied with.

As this module was built from basic BG1 staight track pieces this was chosen to section into two modules. The longer Two-BG1 long module is now module 31A and the shorter One-BG1 long module is 31B. Thay can be plugged together to make a standard length module or used separately. |

|||

| Pictures | . Modules 31A and 31B

The white cut edges have since been painted green. Modules 31A and 31B

The white cut edges have since been painted green.

Another module will be sectioned if necessary. |

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 32 | Straight Filler Module | 2016 | To be Built | To Be Measured |

| Notes | To use modules 21 and 22 on the same side of the display an adaptor module is

need to make up the extra space on the other side of the loop. A module one BG2 long was needed.

This straight adaptor module is built out of foam. It has since proved useful in other displays.

Note: this module should have a lower number but when the modules were inventoried and asigned numbers, this module was overlooked. |

|||

| Pictures | .

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 33 | Straight Swayback Module | September 2017 | In Service | 86mm and +++ |

| Notes | To allow the use of the turnback modules on a table it was necessary

to move the track back about a half module. This module does that. I may

build the mirror image of this module. It has also proved useful with Voyteks' modules.

1/2 of a BG2 on the end of each track with rail and tie strips in the center.

Curves are R5- and R5+, a bit sharp. |

|||

| Pictures | .

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 34 | End Loop 1 | September 2017 | In Service | Non Standard |

| Notes | For years we have wanted a way to easily get inside of the display.

With the display on low tables this is a pain in the back. After contemplating reverse loops

for years I finally built them this summer(2017). The frames fold up into a compact carrying piece.

The track is code 83 rail in Tillig tie strips on cork. The frames were built for my by Jake S.

A Tam Valley Dual Frog Juicer handles the auto-reverse function. Except for moving rails closing up the auto reverse gaps these work well. Tibi suggested a better way to wire them. This was done for VTE 2017 in November 2017. The BR3 (15.6" 396mm) curves are a bit tight for some equipment. They could be rebuilt. The reversing modules do violate a few features of TT-Tracks; they are of a non-standard size and they are not light. The weight is manageable. The size is a bit awkward to manoeuvre through standard door ways but is managable. The verticle protrusions have since been removed. At of VTE 2018, it was decided to rebuild these to a larger radius. R4 will fit with a few modifications. R5 was contemplated but it would require too many extensions to the loop module. In 2019 it was decided that rebulding these to R4 would be too much work for too little return. They would still be bulky and heavy so a new end foam based loop was designed and built in May/June 2019. Now used as return loop for inner staging yard. |

|||

| Pictures | .

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 35 | End Loop 2 | September 2017 | Stored Servicable | Non Standard |

| Notes | The second of two end loops.

These allow us to have easy access to the centre of the display. It also allows us to locate the staging yard and the end loop inside of the display. As the loops fold up scenery has to be very low profile or removeable. Several ideas are being contemplated. 2019 Stored servicable as new larger end loops were built. |

|||

| Pictures | .

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

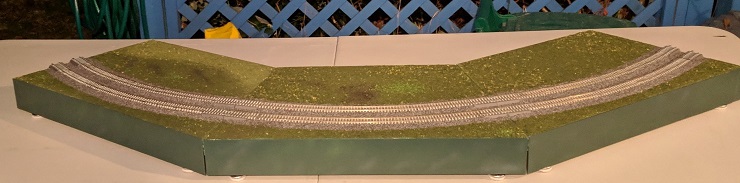

| 36 | 30" Corner 1 | October 2017 | In Service | 86mm |

| Notes | The first 45 degree 30" curve.

For long time we have known that our corner curves (BR4 and BR5) are too sharp for good operation and appearance. After a period of doodling on the computer I came up with several designs for 30", 36" and one metre corners. The size is the square box that a pair of these set up as a 90 degree corner would fit in. As a pair of 30" inch corners would fit inside the corner transporation boxes I was already using, I built a pair. The base is foam. The track is code 83 rail handlaid on Clover Valley PC and wood ties with half BG2 pieces at the ends. Cork roadbed with spacers is under the ties. The curves are nominal BR6 and BR7 (R6 -- 525 mm -- 20.7 in. - R7 -- 568 mm -- 22.4 in.) This module has a power connector now upgraded to a dual connector. Initial impressions are that the trains look much better on these corners and that this is a project to pursue further. This module has leveler feet. The track to the rear is temporary. Althought he result is not pretty, the front corners have been removed so these modules will fit in a standard module box. |

|||

| Pictures | .

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 37 | 30" Corner 2 | October 2017 | In Service | 86mm |

| Notes | The second 45 degree 30" curve.

These corners can be used together or separated by another module as was done at Chilliwack 2017. Their non standard size is making planning for smaller displays difficult. BCSME with its small room will be interesting. At least one set of 31A and 31B modules is necessary. A second set may be useful. In 2019 the end points were clipped so it would fit in a standard module box. |

|||

| Pictures | .

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 38 | Station Module | September 2017 | In Service | 86mm + 129mm |

| Notes | Built on a laser cut base, it features a Model Power Station (A clone of the HO Scale Atlas Station).

A memorial, benchs and flag pole. It has leveller feet. Two 3-d printed tank models will be added to the memorial, a Ram II and a Sherman. |

|||

| Pictures | . Updated scenery. Updated scenery.

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

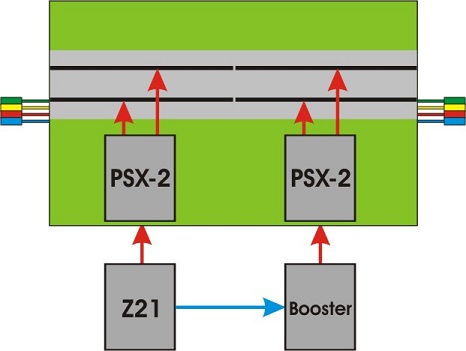

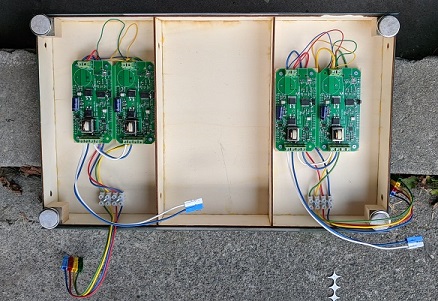

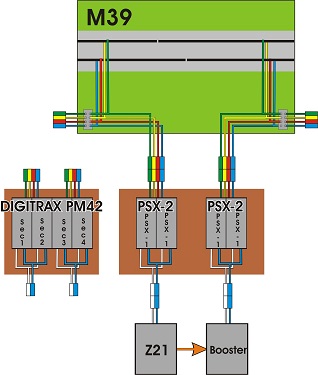

| 39 | Power Module | September 2018 | In service but. . . | 86mm |

| Notes | This is the new module used to connect power to displays.

The track is split in the center and power fed each way through two PSX-2s. This splits the layout into four power districts. Built on a laser cut base. For scenery a power substation would be approriate. |

|||

| Notes | Operation is poor.

In the first setup the reverse loops didn't work properly. The PSX's were bypassed. In the second setup the reverse loops worked perfectly but one unit would shut down when a locomotive passed into its zone. Again the PSXs were bypassed. Investigating further. It is planned to bring the PSXs out from under the module and mount them on their own base. |

|||

| Notes | 2019 - we gave up on the PSXs and just use this module to provide power to the display. | |||

| Pictures | . Schematic of the module. Schematic of the module.

|

|||

| Pictures | . Top of the module. Top of the module.

Bottom of the module. Bottom of the module.

|

|||

| Pictures | .To make it easier to see what the error lights are Module 39 will be rebuilt.

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

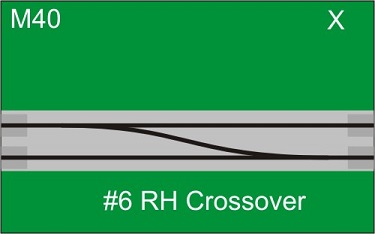

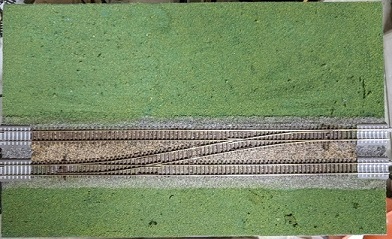

| 40 | RH #6 Crossover Module | 2018-10 | 2018/10 In Service. | 86mm |

| Notes | This is a crossover module using Kuehn #6 turnouts. It is built on a laser

cut module. Turnout control manual for now.

The tracks and turnouts are on N-Scale cork with a .030" Styrene shim under them. The straight sections are Kuehn flex trak. |

|||

| Pictures | . Schematic of the module. Schematic of the module.

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 41 | LH #6 crossover module | 2018-10 | 2018/10 In service. | 86mm |

| Notes | This is a crossover module using Kuehn #6 turnouts. It is built on a laser cut module. Turnout control manual for now. | |||

| Pictures | . Needs more ballast but otherwise ready for servie. Needs more ballast but otherwise ready for servie.

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 42 | Straight Swayback Module | 2018 | 2018-09 in service | 86mm and +++ |

| Notes | This is a partial mirror image of module 33. The track across the module

has gentler curves than module 33. This results in a non standard track location on the left;

the tracks are centered on the edge of the left side of the module.

It is built with 1/2 of a BG2 on the end of each track with code 70 rail

and tie strips in the centre, on a laser cut module.

There may come a need for a mirror image of this module. That would allow for modules with tracks centred on them. As module 33 has already been rebuilt once, it will be left the way it is and a new module the mirror image of this one will be built. Curves are around R10 with easements. |

|||

| Pictures | .

|

|||

| Pictures | .A few ideas with the tracks centered on the modules rather than offset to the front.

|

Module Number |

Module Description | Year in Service |

Status | Offset |

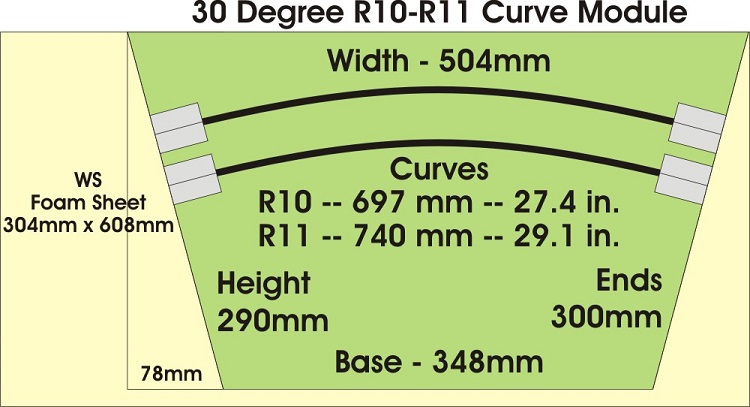

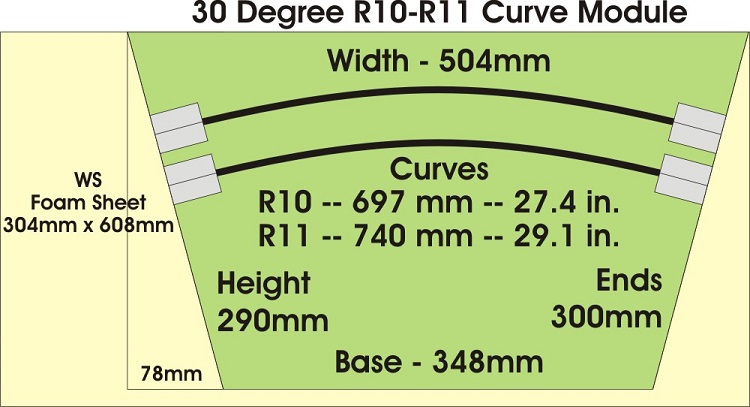

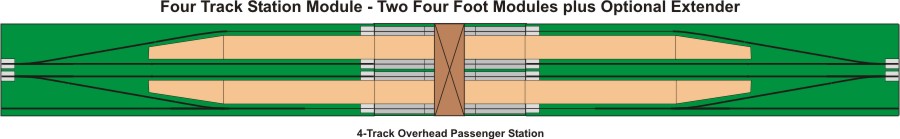

| 43 | 30 Degree Corner | 2018 | Built | 86mm |

| Notes | A 30 degree corner with R10 / R11 curves.

A R10 curve is 697 mm or 27.4 in. - HO equivalent 36" A R11 curve is 740 mm or 29.1 in. - HO equivalent 38.25". Built out of foam. 1/2 BG2 on edge. Peco code 75 rail in concrete tie strips. Fits in a standard module box. Power corner with dual Anderson Powerpole Connector. |

|||

| Pictures | .

|

|||

| Pictures | .  Three corner set from the front. Three corner set from the front.

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 44 | 30 Degree Corner | 2018 | Built | 86mm |

| Notes | A 30 degree corner with R10 / R11 curves.

Built out of foam. Fits in a standard module box. |

|||

| Pictures | .  Three corner set from the back. Three corner set from the back.

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 45 | 30 Degree Corner | 2018 | Built | 86mm |

| Notes | A 30 degree corner with R10 / R11 curves.

Built out of foam. Fits in a standard module box. |

|||

| Pictures | .  Thirty degree corner set compared to 45 degree corner. Thirty degree corner set compared to 45 degree corner.

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 46 | Filler Module | 2018 | Buiilt | 86mm |

| Notes | A BG1 module (1/3 module) built out of leftovers from the 30 degree corners.

Built out of foam. Sceniced. Basic feet. |

|||

| Pictures | .

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 47 | Filler Module | 2018 | Built | 86mm |

| Notes | A BG2 module (1/6 module) built out of the leftovers from the 30 degree corners.

Built out of foam. Sceniced.Basic feet. |

|||

| Pictures | .

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| Module Number |

Module Description | Year in Service |

Status | Offset |

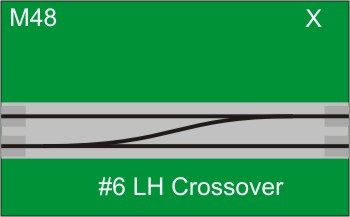

| 48 | LH #6 crossover module | In service at Western Rails 2019 | In service | 86mm |

| Notes | This crossover module uses #6 Kuehn turnouts.

It makes a matched pair of #6 RH and LH crossovers. Turnout control currently manual but planning to use a Tam Valley Turtle decoder to drive two MP1s. Still needs back fascia and grass touched up. |

|||

| Pictures | . Schematic of the module Schematic of the module

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

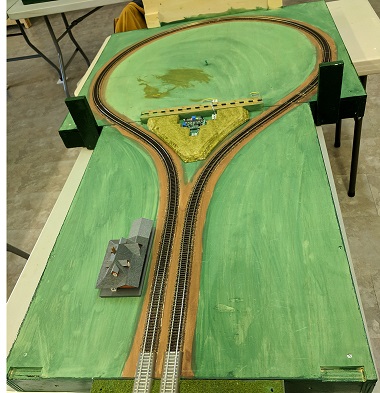

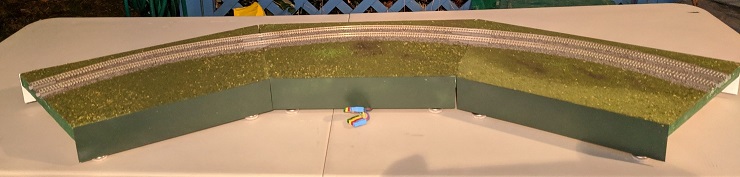

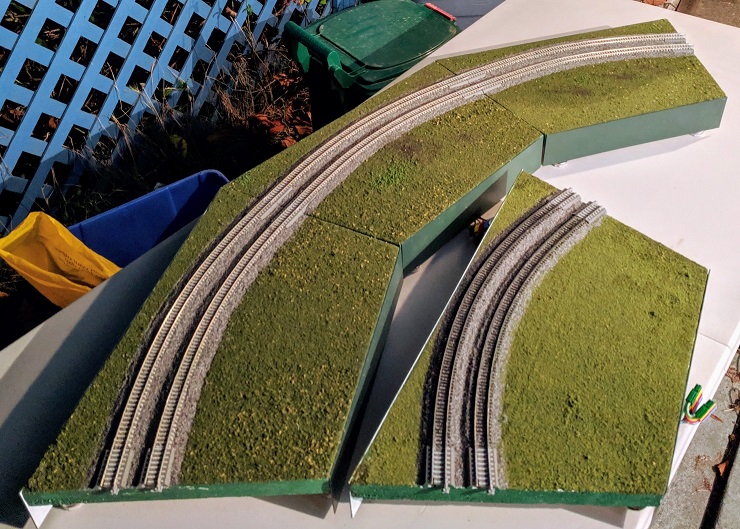

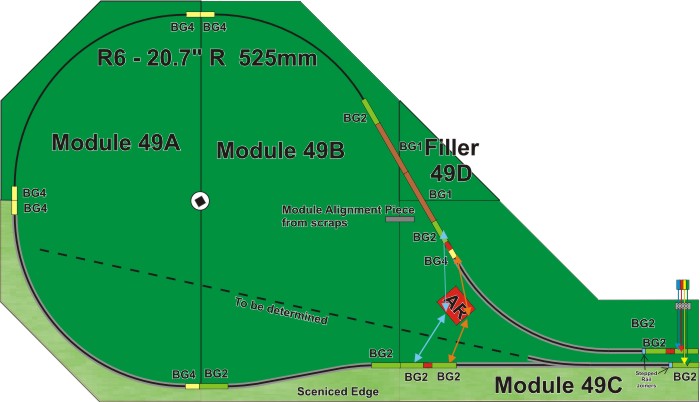

| 49 | Teardrop End Loop | In Service 2019/06/18 | Painitng and scenery need work. | Standard |

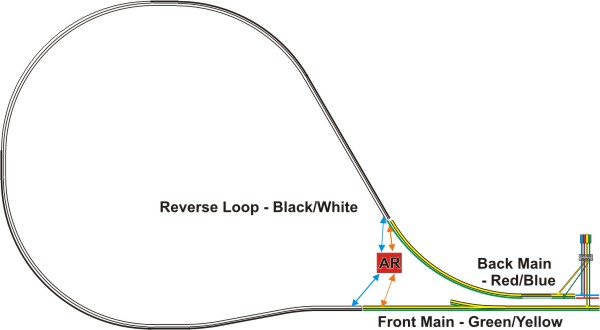

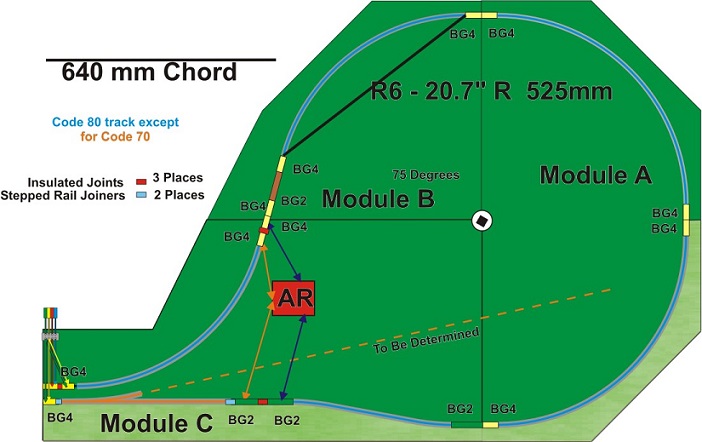

| Notes | Kuehn Code 70 flex track on cork roadbed. Uses Tillig bedding track to connect the three (+1) pieces.

Main curve R6. Basic scenery on front (public) side. Overall size 4' x 7' comprised of four pieces. Two 2'x 4' with one or two clipped corners. One piece 2' x 3' with right end narrowed to standard module width. One filler triangle. As of June 15, 2019, construction and wiring complete. Finishing started. First run - BCSME test June 18, 2019. Ran perfectly. Now to finish basic scenery. Tibi is planning on building an oil refiner to sit on top of this module. |

|||

| Pictures | . Schematic of the module Schematic of the module

|

|||

| Pictures | . Reverse Loop Wiring Reverse Loop Wiring

|

|||

| Notes | Power for both main lines comes in by rail joiners or the track power connector.

The Back Main (Red/Blue) ends at insulated rail joiners after one track segment. The front main is connected to the back main track after the insulated rail joiners. This is so the Auto Reverser (Dual Frog Juicer) is only dealing with power from one booster. It gets its power from the track segment just before the reversing gaps. The output of the Auto Reverser goes to the reverse loop tracks just after the reversing gaps. |

|||

| Notes | February 2020. Alignment and locking mechanism added to lock sections of loop together. | |||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 50 | Teardrop End Loop | In service 2019 at Salt Lake City | Scenery needs work | Standard |

| Notes | Modified mirror image of module 49.

Redesigned to use fewer pieces and be shorter. Overall size 4' x 6'. Mixed Code 80 and Code 70 flex track on cork roadbed. Uses Tillig bedding track to connect the three (+1) pieces. Main curve R6. Basic scenery on front (public) side. Three piece loop. One 2'x 4' with two clipped corners. One four foot module with end narrowed to one foot. One piece 2' x 2 1/2' Clipped to complete curve. Given the number of coal cars we have, tbis might be a good location fo a coal mine. |

|||

| Pictures | . Schematic of the module Schematic of the module

|

|||

| Notes | February 2020. Alignment and locking mechanism added to lock sections of loop together. | |||

| Module Number |

Module Description | Year in Service |

Status | Offset |

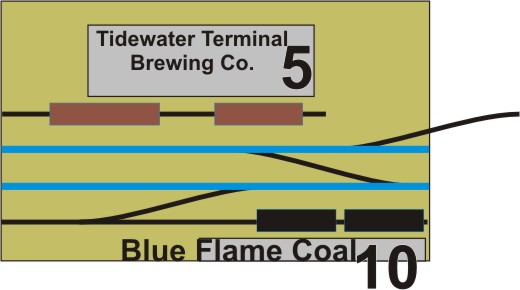

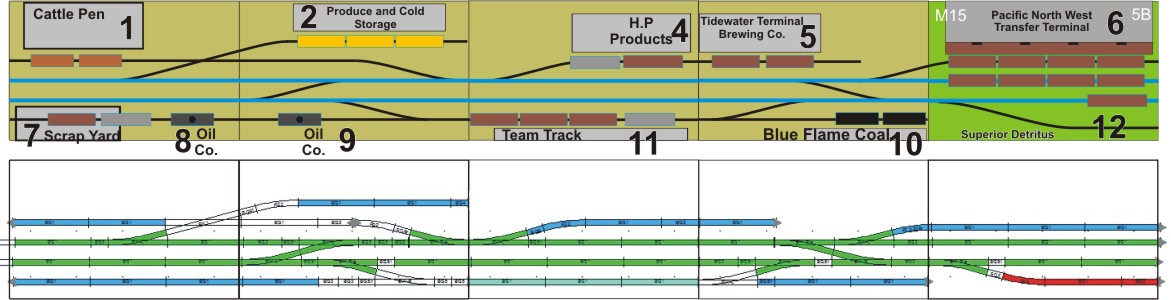

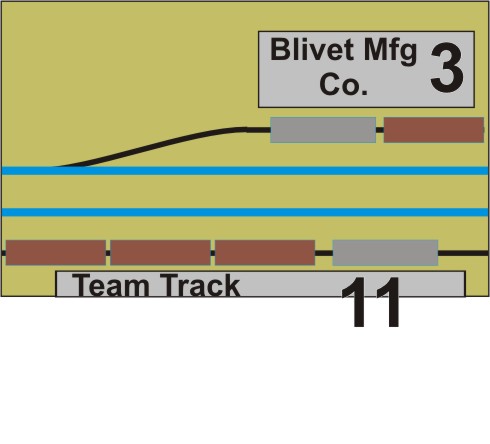

| "nn" | Industrial Back area | Slow Construction | Module M15 finished | 86mm |

| Notes | All the 15 degree turnouts being made surplus will be

used to make an industrial switching area. Accesed by module 36.

Originally designed for laser modules it has been changed to foam to reduce the cost. This set of modules is designed with the two mainlines running through them on standard spacing(two green tracks). When used behind the main set of modules, industry track 12 (red track) is the access to the main layout. Blue tracks are industries. Projected industries are:

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

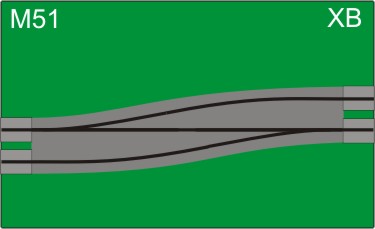

| 51 | Standard Module | 2020 | Buiilt | 86mm |

| Notes | The third module of the Industrial Area.

Built out of white foam. Basic feet. |

|||

| Pictures | .

|

|||

| 52 | Standard Module | 2020 | Buiilt | 86mm |

| Notes | The fourth module of the Industrial Area.

Built out of blue foam. Basic feet. |

|||

| Pictures | .

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 53 | Standard Module | 2020 | Buiilt | 86mm |

| Notes | The fifth module of the Industrial Area.

Built out of blue foam. Basic feet. |

|||

| Pictures | .

|

|||

| Conjecture - These are ideas that may or may not come fruition. Building any of these modules will require more storage boxes. | ||||

| Module Number |

Module Description | Year in Service |

Status | Offset |

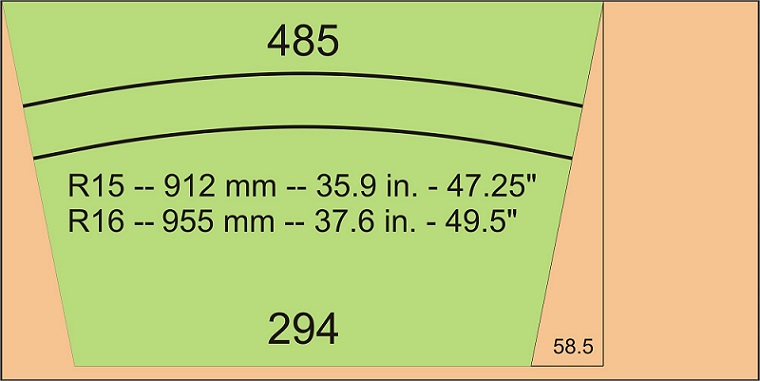

| 54, 55, 56, 57 | 22.5 Degree Corners | April 2022 | Built and in service | 86mm |

| Notes | Designed to be equivalent to a 48" curve in HO Scale.

22.5 degrees makes a module small enough to fit in a standard module box. Four are needed to make a 90 degree curve. |

|||

| Pictures | .

Schematic of module. Schematic of module.

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 58 | RH #8 crossover module | April 2022 | In Service | 86mm |

| Notes | This is a crossover made from #8 turnouts built with a Fast Tracks jig. Also has a Kuhen #6 RH Turnout for access to the back tracks.

23.5" long module built on a slightly trimed 12" x 24" painters panel. #8 Turnouts controled by Tam Valley Servo Control Module. #6 turnout manual. |

|||

| Pictures | . #8 RH Crossover module. #8 RH Crossover module.

|

Module Number |

Module Description | Year in Service |

Status | Offset |

| 59 | 30 Degree Corner | April 2022 | Built | 86mm |

| Notes | A 30 degree corner with R10 / R11 curves.

A R10 curve is 697 mm or 27.4 in. - HO equivalent 36" A R11 curve is 740 mm or 29.1 in. - HO equivalent 38.25". Built out of foam. 1/2 BG2 on edge. Peco code 75 rail in concrete tie strips. Fits in a standard module box. |

|||

| Pictures | .

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| 60 and 61 | 30 Degree Corner | To be Built 2022 | In progress | 86mm |

| Notes | A 30 degree corner with R10 / R11 curves.

A R10 curve is 697 mm or 27.4 in. - HO equivalent 36" A R11 curve is 740 mm or 29.1 in. - HO equivalent 38.25". Built out of foam. 1/2 BG2 on edge. Peco code 75 rail in concrete tie strips. Fits in a standard module box. |

|||

| Pictures | .

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

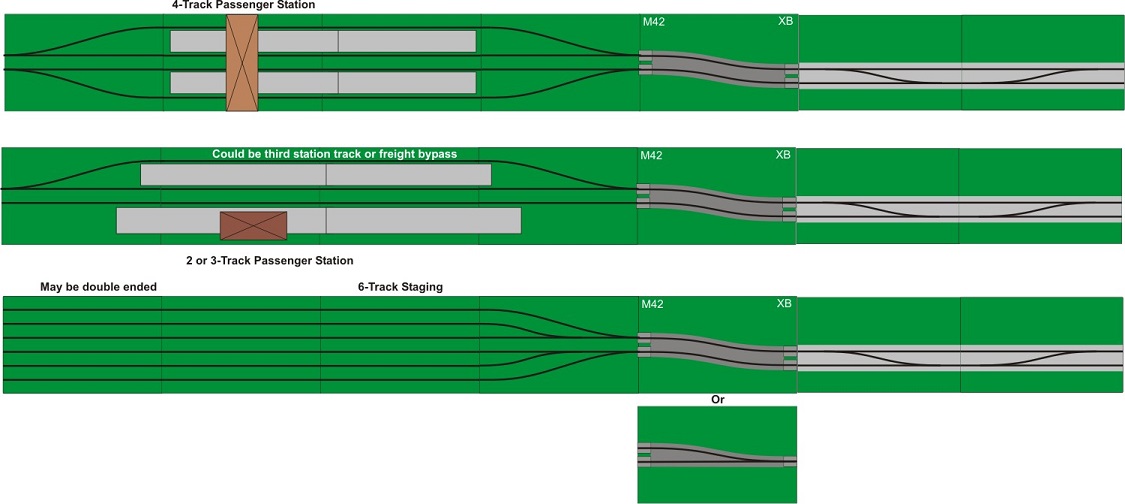

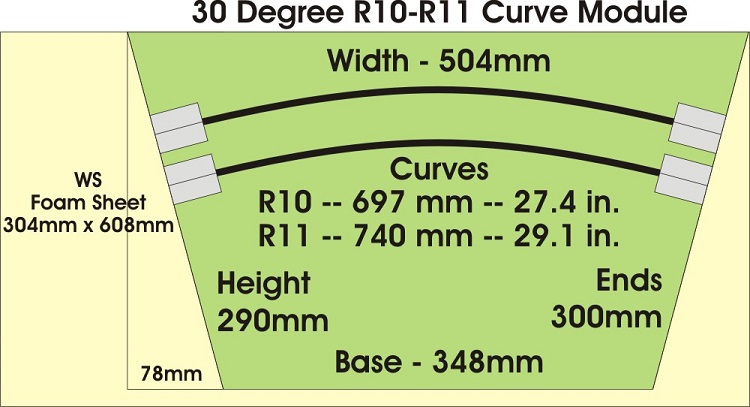

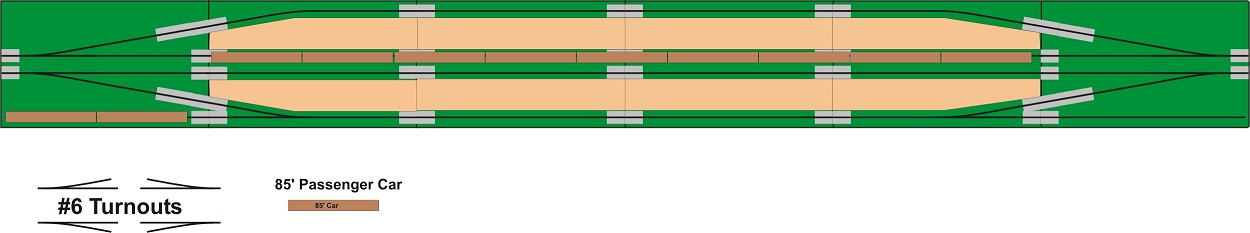

| nn | New run through station module set. | 2020? | Started | 86mm |

| Notes | With the arrival of new larger curve corner modules,

the station corner will be retired soon. This means we need a new station module set.

As the use of four foot long modules in the new Teardrop end loops has shown the practicallity of longer modules, this will be made as two four foot sections with optional extension modules. This will remove a lot of inter module connections. These will be 12" x 48" painters panels squared up. |

|||

| Pictures | . Schematic of the new station module set Schematic of the new station module set

|

|||

| Pictures | . Schematic of the new station module set with four foot modules. Schematic of the new station module set with four foot modules.

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| "nn" | Swayback module with RH Crossover | To be built 2020 | 86mm | |

| Notes | This is to be a mirror image of module 42.

Some doodling was done to see if it could also include a crossover. As it looks like it will fit, the module will be built that way. Turnout control to be determined. |

|||

| Pictures | . Schematic of the module Schematic of the module

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| nn | LH #8 crossover module | Conjecture | 86mm | |

| Notes | This will be a crossover made from #8 turnouts built with a Fast Tracks jig.

It will be be a 24" long module built on a Woodland Scenics foam sheet. Turnout control to be determined but it will need something to control and power route the Fast Tracks turnouts. This will be built to balance the #8 RH Crossover module. Will hold of on building this module until we see the Peco Long Radius turnouts. |

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

| nn | Road Over Pass Module | Have bridges, track and foam. | 86mm | |

| Notes | This will be a full length module with a bridge over a sunken road

using modified Atlas N-Scale through Girder bridges with different CNR Slogans on them.

Road will need to be 1 1/2" deep (15' clearance). Terrain will slope away from the track. Track: BG3, BG1, Bridge, BG1. |

|||

| Pictures | . Schematic of the module Schematic of the module

|

|||

| Module Number |

Module Description | Year in Service |

Status | Offset |

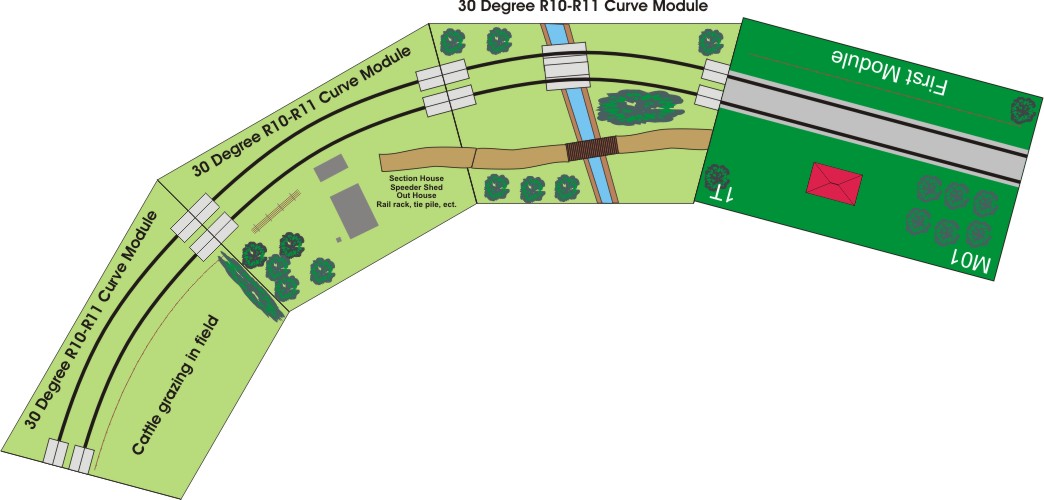

| MP55-MP57 | New Corner Module Set | Planning | 86mm | |

| Notes | This will be a replacement curve set for Legacy Module 9. It is intended to duplicate the scene on Module nine on these three modules. The bridge will be on the first module. The Railway Service Structures will be on the second module and the third module will be a field with cattle grazing. | |||

| Pictures | . Schematic of the corner modules Schematic of the corner modules

|

|||

|

|

|||||

|

||||||

"TT-Tracks©" wordmark Copyright W.R.Dixon.

Contact Bill Dixon

Home